“…We were saving over $100K a year, just by switching to GoFormz.”

GOFORMZ CASE STUDY

AT-A-GLANCE

Needed a digital solution to the time consuming, manual processing of approximately 200 paper forms a day –– without risking data loss.

Implemented GoFormz to simplify and expedite data capture, while significantly reducing time and administrative manpower spent processing and organizing completed documents.

THE FULL STORY

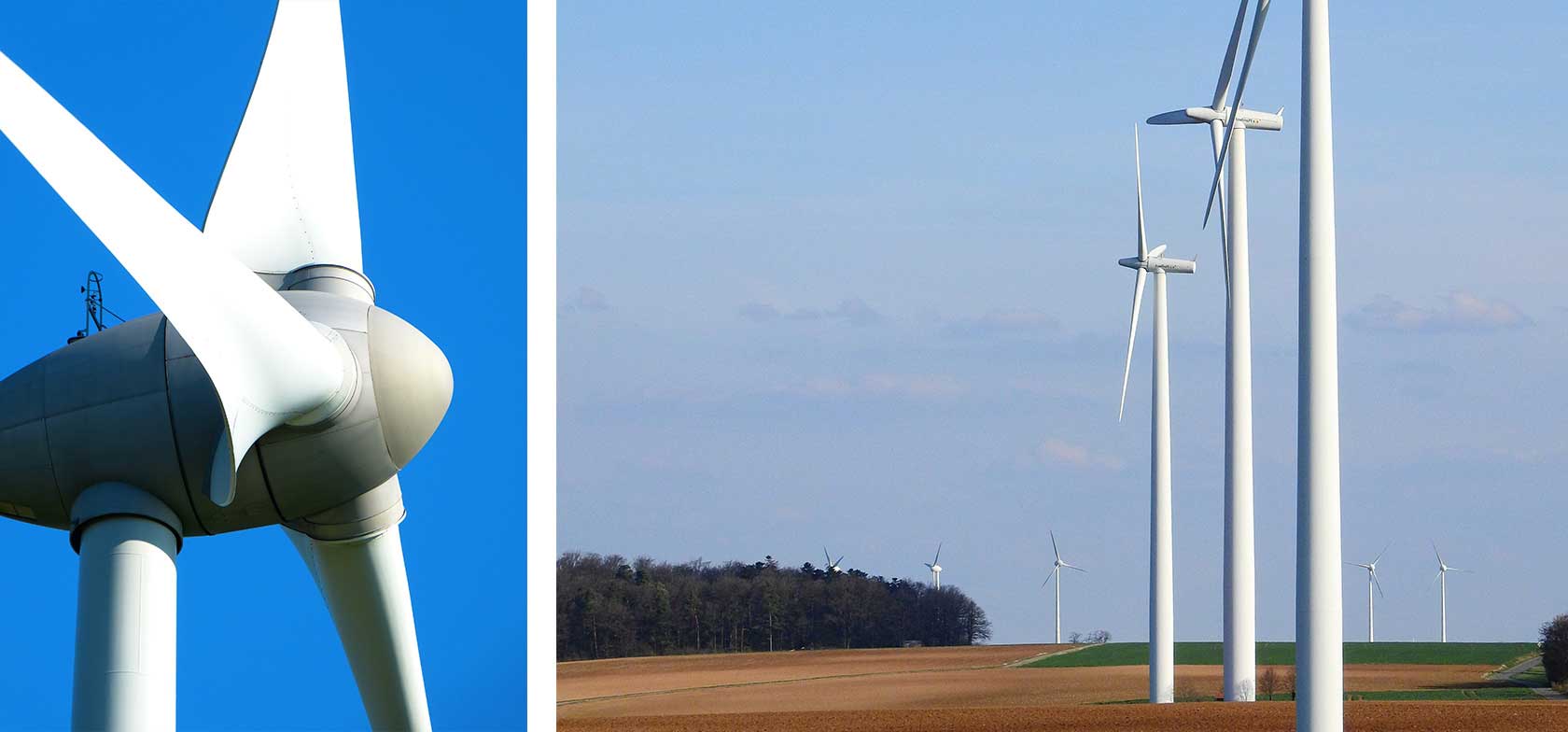

Vestas provides sustainable energy solutions, “designing, manufacturing, installing and servicing wind turbines” to 79 countries. With over 23,000 employees, Vestas has positioned itself as an industry leader by harnessing collected data to “interpret, forecast, and exploit wind resources and deliver best-in-class wind power solutions”. Vestas’ reliance on the accuracy of their collected field data inspired their pursuit of a more reliable and secure data capture platform.

Vestas’ global presence and reliance on accurate, timely data, was coupled with an onslaught of paper forms and administrative demands. Tony Tharp, a Senior Technical Support Technician at Vestas’ Brighton, Colorado manufacturing branch, was determined to relieve the overwhelming demands of the 200 forms completed within his location daily. These paper forms were completed by hand, by mobile team members, and would then be manually scanned, emailed, renamed and filed by a dedicated team. This process required a large amount of time, and was riddled with additional obstacles, for example, frequently missing data in form fields and form damaged by weather.

“These were vital documents that had to be accurate, and had to be done within certain time periods,” Tony explained. His team, which handles Vestas’ Brighton location’s wind turbine manufacturing support (handling work instructions, inspections, the manufacturing control process and more) sought a solution to the unreliable, manually gathered data.

Vestas’ initial foray into digital forms, using another form platform, was frustrating and unreliable, with Tony’s team navigating irritating app crashes and upload errors. “We were having problems after problems,” Tony explained. “We couldn’t save the files to the device, it would send it to the cloud… but if there were server issues it wouldn’t upload, and you would lose days worth of data.” With Vestas’ reliance on accurate, consistent data, an alternative to their current form provider became glaringly obvious.

“GoFormz cut the time in half for building forms and populating the fields that we needed.”

Upon discovering GoFormz, Tony discovered immediate time savings. Also responsible for the digitization of another Vestas plant (which produced up to 800 sheets of collected data a day) Tony was pleased to discover GoFormz enabled him to create Templates that could be seamlessly transferred between GoFormz users and accounts, significantly simplifying the Template building process. “The [Template] Editor was really easy to use,” Tony explained. “GoFormz cut the time in half for building forms and populating the fields that we needed.” Rather than struggle with a cumbersome interface, or email scanned documents, Tony’s team could now easily build, distribute and fill out mobile forms.

Tony introduced Vestas to GoFormz, beginning with four digitized forms and within two days his team was sold. They were thrilled with not only the usability of the GoFormz interface, but also the variety of options presented when routing completed forms to another device or computer. This was a welcome change, especially considering the large amounts of data that had been lost by their previous form provider, while attempting to upload information to the Cloud.

Today, the Vestas team now use a variety of mobile forms via GoFormz, and continue to witness positive results and feedback. Tony has been especially impressed with how GoFormz has optimized Vestas’ inspections. The Vestas inspection workflow involves team members receiving the serial numbers of products they are maintaining, and entering information about that product. “What’s nice is that when [users] are filling [inspection forms] out, they’ll be in and out of network access. So, [with GoFormz] managers can keep a live record of if their guys are filling out the right ones, if they're filling them out correctly, and then they can immediately spot check.” Once inspection forms are completed, they can be showed to customers as proof that their products are being properly maintained while at the Vestas facility.

Two key GoFormz features that have optimized the Vestas inspection process, as well as equipment preventative maintenance, are Image fields and Barcode Scanning. Before GoFormz, if there was an issue with a specific piece of equipment, a Vestas team member would need to handwrite a report detailing the issue, take a picture, type up the report, upload and attach the image file, and then send the report to relevant departments. Now, Tony explains, “With GoFormz we can take a picture on the spot, scan barcodes for serial numbers, fill in the issues, and send it to the department that needs to investigate the issue… within minutes.”

By switching to GoFormz, Vestas realized immediate, compelling savings. “…We were saving over 100K a year, just by switching to GoFormz,” Tony explained, citing Vestas' reduced personnel demands and processing efficiency. “Time savings is constantly going up and up.” Eager to share this optimization opportunity with other Vestas plants and teams, Tony has presented his findings to Vestas’ global IT team, and the savings speak for themselves.

“It was time savings, the day I started using it.”

“We've always had a vision of being paperless, 100%, [with GoFormz] it seems like we can reach that goal a lot quicker, within the next year or two.”.