Oldcastle prefabricated bathrooms save construction projects time and money

Oldcastle is North America’s leading manufacturer of building products and materials. As the industry’s only national prefabricated bathroom manufacturing company, Oldcastle has installed more than 5,000 bathrooms in commercial projects across North America. Oldcastle factory-built bathrooms provide customers a quality, turnkey solution to one of the largest problem areas on a construction job site. The company’s precision manufacturing and rigorous pre-delivery inspection process eliminate the on-site bathroom punch list, shaving up to three months off the construction schedule. Oldcastle turned to GoFormz to fine-tune that production process and save costs within their own company.

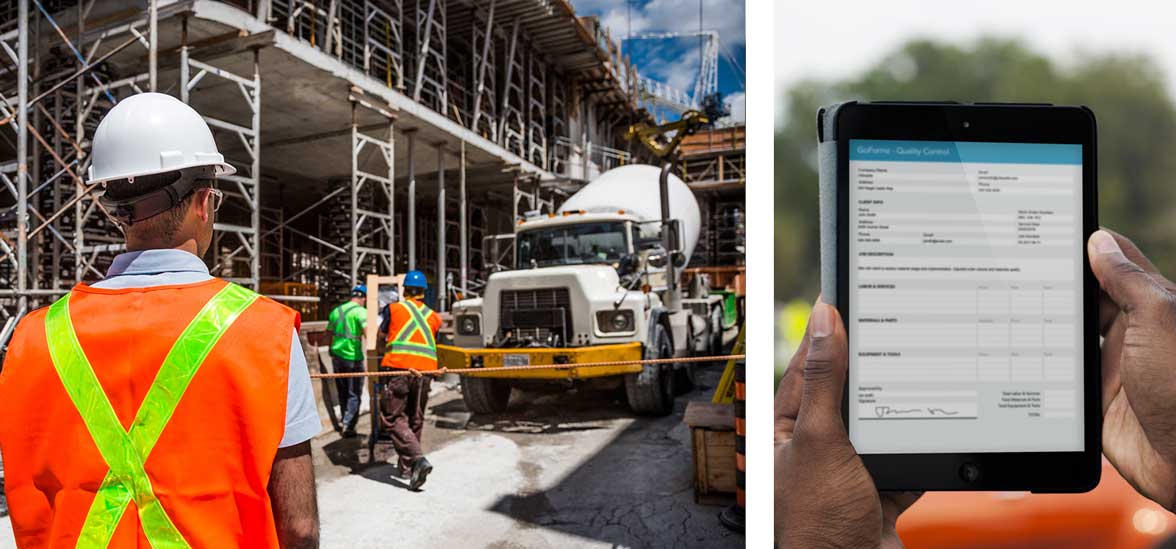

GoFormz eliminates paperwork and ensures that quality control documentation gets completed on time

Before GoFormz, Oldcastle required workers to complete a 17-page document to manage quality on every bathroom produced. With 12-15 bathrooms produced daily, the paperwork quickly overwhelmed the factory workers. In addition, forms weren’t customized for each project, and many check points didn’t apply to certain projects. As a result, factory workers didn’t complete the forms during production, causing thousands of quality control pages to pile up. Since the documentation was required when the bathroom shipped to the customer, workers had to complete the forms after the fact. Inevitably, inaccuracy occurred and management had very little visibility into production issues and inefficiencies.

Oldcastle evaluated several mobile forms solutions to eliminate paperwork from their production process, and initially selected ProntoForms. But ProntoForms quickly proved inadequate when Oldcastle had to hire an IT resource to build the online forms they needed. GoFormz was the clear choice for getting their existing quality control forms on mobile devices, without having to hire more resources to do it.

Oldcastle relies on GoFormz to analyze production efficiency

With GoFormz, Oldcastle can create customized quality control forms for each bathroom produced. Then it’s easy for factory workers to input production data from a mobile device right on the factory floor. To ensure that all documentation gets produced on time, workers can’t move to the next project phase until the quality control manager approves the form. Photos of each phase of the project are included with the form, so the customer can see the condition of the bathroom before and after it ships.

Since quality control forms are completed as production happens, management can analyze the data and pinpoint inefficiencies. With GoFormz, Oldcastle can run reports based on all the data they collect, like inspection start and stop time, to determine which processes take too long or which groups are not working effectively. They can also spot trends more easily. For example, if factory workers report that bathroom tile consistently cracks, Oldcastle can work to determine whether it’s a tile quality or assembly issue.

GoFormz gives Oldcastle insight to eliminate extra costs

Oldcastle used insight from GoFormz to uncover wasted painting costs in their bathroom production. During a typical project, a bathroom ceiling gets painted three times throughout the assembly process. With the GoFormz quality control form in place, factory workers reported instances where a fourth coat of paint was added at the end of the assembly. They noted that the extra coat of paint covered marks and scratches that occurred during the final production phase. Because this data was reported with GoFormz, management could run reports to determine that the extra coat was applied 90% of the time. They decided to shift the third coat of paint to the end of the assembly line, eliminating the fourth coat all together. As a result, Oldcastle saved $500K in paint costs per year. “With GoFormz, our quality control process is simpler, but more powerful,” notes Parimal Shukla, Manufacturing Engineer, at Oldcastle. “Quality control is only as good as the participants, and GoFormz empowers our factory floor to give us insight that saves costs.”

“Quality control is only as good as the participants, and GoFormz empowers our factory floor to give us insight that saves costs.”

GoFormz gets damage control under control

Before GoFormz, Oldcastle struggled with damaged parts and reporting issues to vendors. For every 50 parts required to build a bathroom, 20 would arrive damaged. However, the receiving department had no way of recording the damage for the project manager, or reporting the issue back to the supplier. As a result, a bathroom project would run out of key supplies, like mirrors, after the supplier’s 30-day dispute window had closed. With GoFormz, the receiving department can record damage on an electronic form, which automatically reports the issue to the project manager and the vendor. And Oldcastle can track inventory in real-time.

GoFormz integrates with Box to improve collaboration at Oldcastle

Oldcastle uses Box for all document storage, sharing, and collaboration. GoFormz is completely integrated with Box, so quality control documents completed by factory workers are available to project managers in real-time. Although the documents reside in Box, GoFormz makes all the data available to run reports on production efficiency.

“We believe that GoFormz gives us a competitive edge,” states Shukla. “Our customers aren’t impressed with paper, but GoFormz is more than they ever expected.”